DIY Wooden Toy Projects That Are Perfect for Gift Shops and Craft Fairs

Looking for a unique and profitable way to showcase your crafting skills? Handmade wooden toys are a timeless classic that always captures the hearts of children and adults alike. These charming creations are not only beautiful but also environmentally friendly, making them a perfect choice for eco-conscious shoppers. With a little creativity and some basic woodworking skills, you can craft a variety of wooden toys that will fly off the shelves at gift shops and craft fairs.

The best part? Wooden toys are incredibly versatile. You can create simple, classic designs like rocking horses and pull toys, or delve into more intricate projects like miniature dollhouses and intricate puzzles. The possibilities are truly endless, allowing you to express your personal style and cater to a wide range of tastes.

Why Wooden Toys are Perfect for Gift Shops and Craft Fairs

Wooden toys offer several advantages that make them highly desirable for both sellers and buyers:

- Uniqueness: Handmade wooden toys stand out from the mass-produced plastic toys found in most stores, offering a unique and special touch.

- Durability: Made from natural, sturdy materials, wooden toys can withstand the rigors of playtime and last for generations.

- Sustainability: Wooden toys promote environmental consciousness by using renewable resources and reducing plastic waste.

- Creativity: Wooden toys often encourage open-ended play, allowing children to use their imaginations and develop their creative skills.

- Appeal: The natural beauty and handcrafted quality of wooden toys attract a broad range of customers, from parents seeking timeless toys to collectors looking for unique pieces.

DIY Wooden Toy Project Ideas

Get your creative juices flowing with these inspiring wooden toy project ideas that are sure to be crowd-pleasers:

Classic Wooden Toys

- Rocking Horse: A timeless classic that brings joy to children of all ages. You can customize the design with different paint colors, patterns, and even add a saddle for extra fun.

- Pull Toy: Simple yet engaging, pull toys encourage crawling and walking while providing hours of entertainment. Consider adding wheels, colorful patterns, and even a small character to the toy.

- Wooden Blocks: These versatile building blocks can be used for endless imaginative play. You can create different shapes, sizes, and even add letters and numbers to enhance learning.

- Wooden Puzzles: A challenging yet rewarding activity, wooden puzzles help develop problem-solving skills. You can create simple shape puzzles or more complex picture puzzles for older children.

Imaginative Wooden Toys

- Miniature Dollhouse: Bring a child's imagination to life with a charming dollhouse. You can create a simple structure or add intricate details like furniture, wallpaper, and accessories.

- Wooden Train Set: A classic for a reason, wooden train sets offer endless possibilities for storytelling and creative play. You can create tracks, stations, tunnels, and even add miniature people and animals.

- Wooden Play Kitchen: Encourage imaginative play with a cute and functional wooden play kitchen. You can create a simple stovetop or include a full kitchen set with cabinets, a sink, and even a refrigerator.

- Wooden Carving Toys: These simple toys are perfect for toddlers, encouraging them to explore their creativity and motor skills. You can create simple shapes like animals, vehicles, or letters.

Tips for Success

Here are some helpful tips for creating successful wooden toy projects:

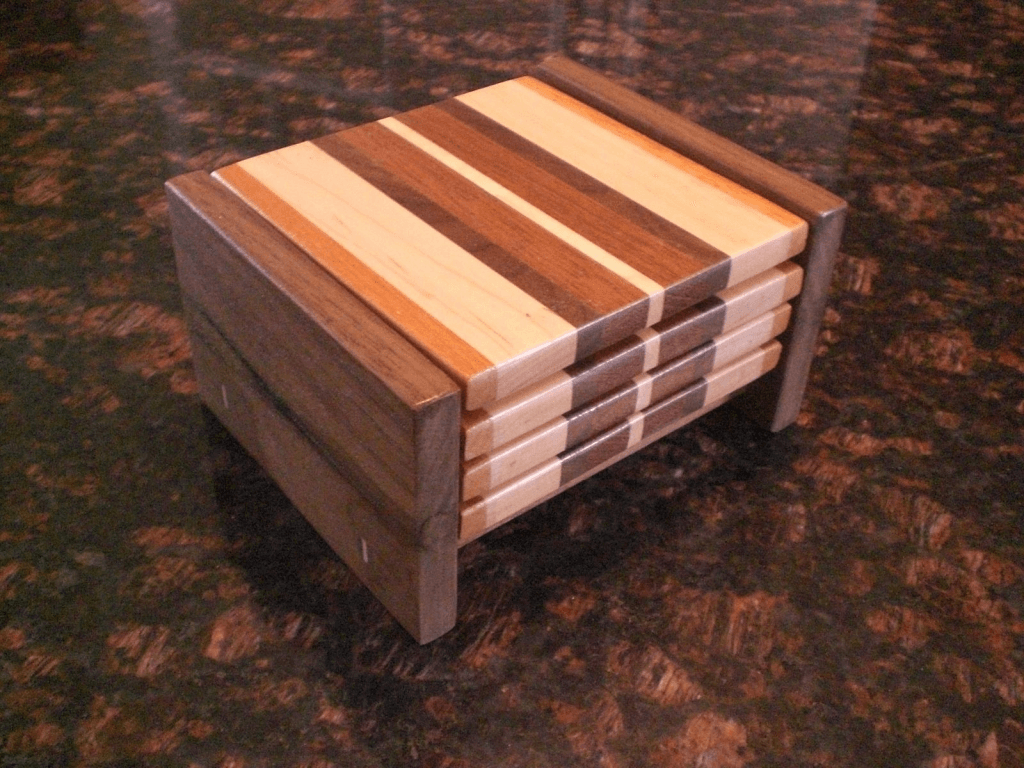

- Choose the Right Wood: Select wood that is durable, smooth, and safe for children. Popular options include maple, cherry, and pine.

- Pay Attention to Safety: Ensure all sharp edges are sanded smooth, and avoid using paints or finishes that contain harmful chemicals.

- Get Creative with Paint and Finishes: Use non-toxic paints and finishes to add color and detail to your toys. You can also try natural stains or waxes for a more rustic look.

- Consider Packaging: Present your toys in attractive and eco-friendly packaging to enhance their appeal. You can use kraft paper, burlap, or recycled materials.

- Pricing Strategically: Set realistic prices for your toys, considering your materials, time investment, and the market value of similar products.

- Promote Your Products: Take high-quality photographs of your toys and share them online and through social media. Participate in craft fairs and market events to reach a wider audience.

With a little effort and creativity, you can turn your woodworking skills into a thriving business selling delightful wooden toys. These handmade treasures are sure to bring joy and wonder to children and adults alike, making them a perfect addition to any gift shop or craft fair.